-

100 to 500 kg / hour

-

easily operated

-

floor space required: 10 meters x 2.2 meters

|

|

|

|

|

- |

100 to 500 kg / hour |

|

|

- |

easily operated |

|

|

- |

floor space required: 10 meters x 2.2 meters |

|

|

|

|

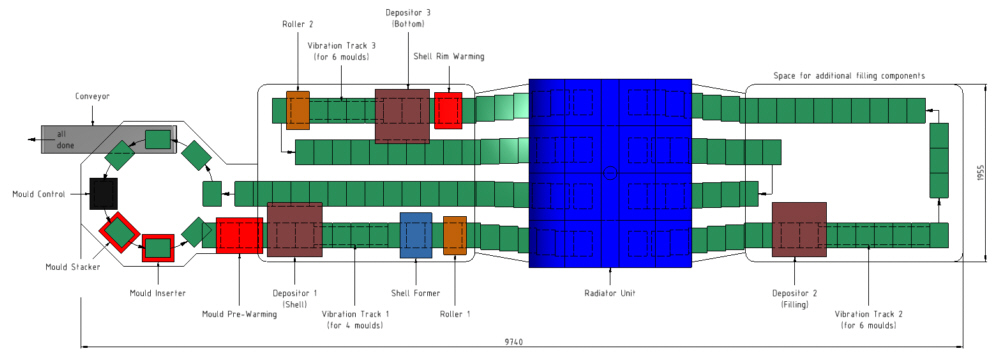

PLANT WS1 - TECHNOLOGY

Our plant WS1 is designed for the production of filled chocolates and bars.

According to standard WS1 is operated with polycarbonate moulds of the size of 275 mm x 205 mm.

The moulds lie together with their long sides. Thus they form a group. With every cycle all moulds are pushed further for the next position at the same time. The moulds are pushed by servo-driven cylinders.

By arranging four of these lanes next to each other we get a compact plant, having area requirements of only 22 square meters.

Our plant WS1 is builded up from a rack for shell forming and bottoming, a rack for the fillings and a group of radiators as link. A demoulding unit is flanged on.

COMPONENTS

|

MOULD PREWARMING MPW1 |

|

|

VIBRATOR VHE1 |

|

|

SHELL RIM WARMING SRW1 |

|

|

DEMOULDING DMR1 |

|

|

RACK with servo-drives and valve units |